-

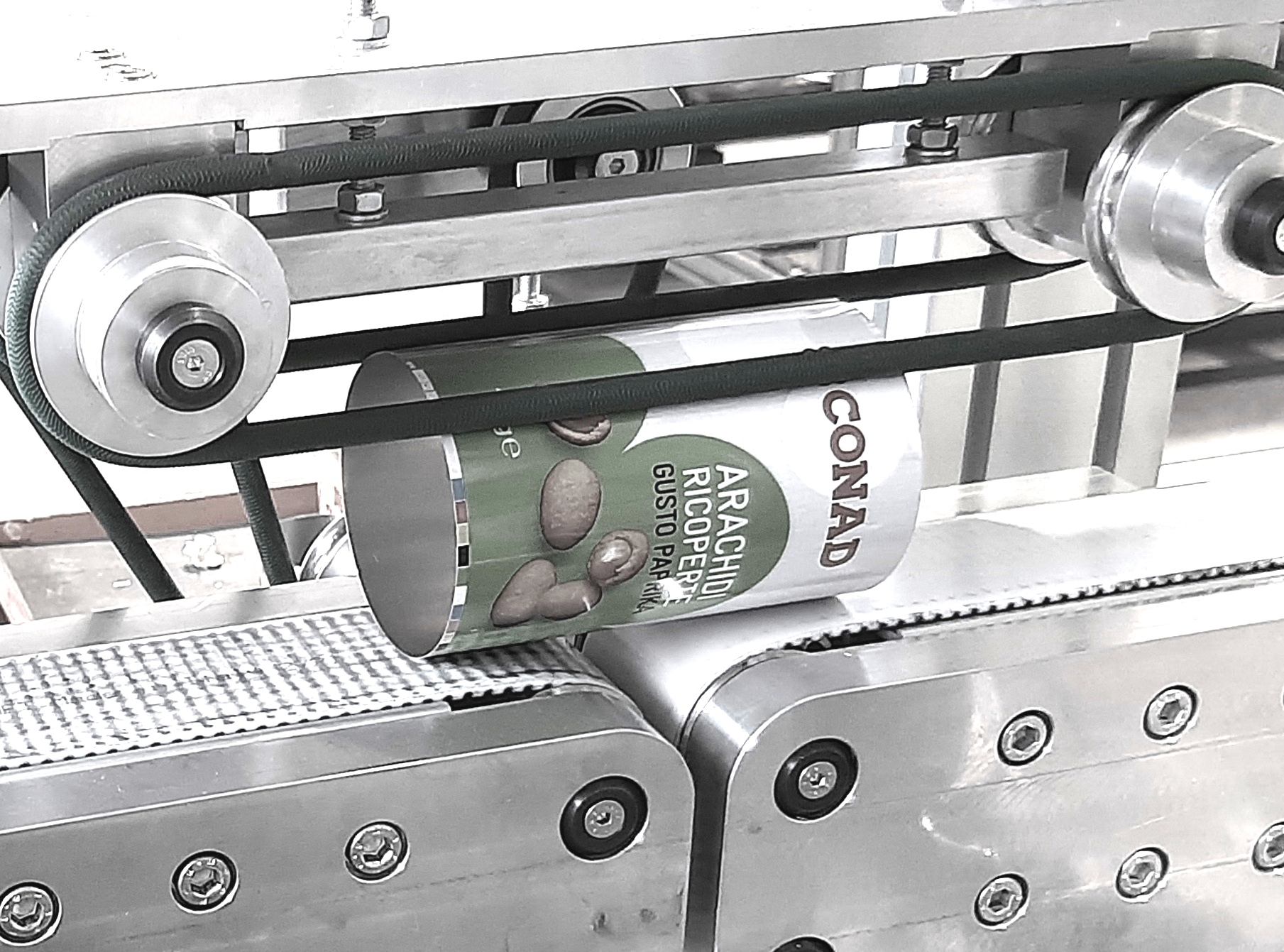

Field service

Identification of the causes of the fault and restarting the line by repairing the line whereas possible. We put all our experience, analysis and problem-solving skills at the service of the customer, as well as the speed of intervention, to get the business restart as soon as possible.

-

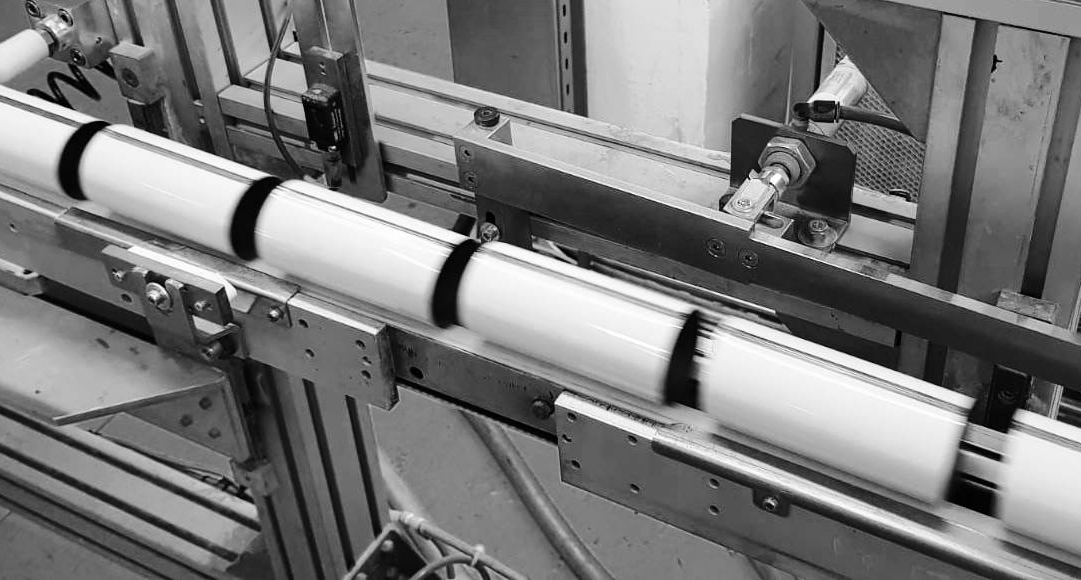

Overhauls

Programmed maintenance of lines. Supply and replacement of electrical and mechanical components in order to maintain efficiency and prevent future malfunctions due to machinery wear and obsolescence. It can be carried out both at customer’s site and at the MEPALINE workshop, depending on the extent of the intervention and the time available for the activity.

-

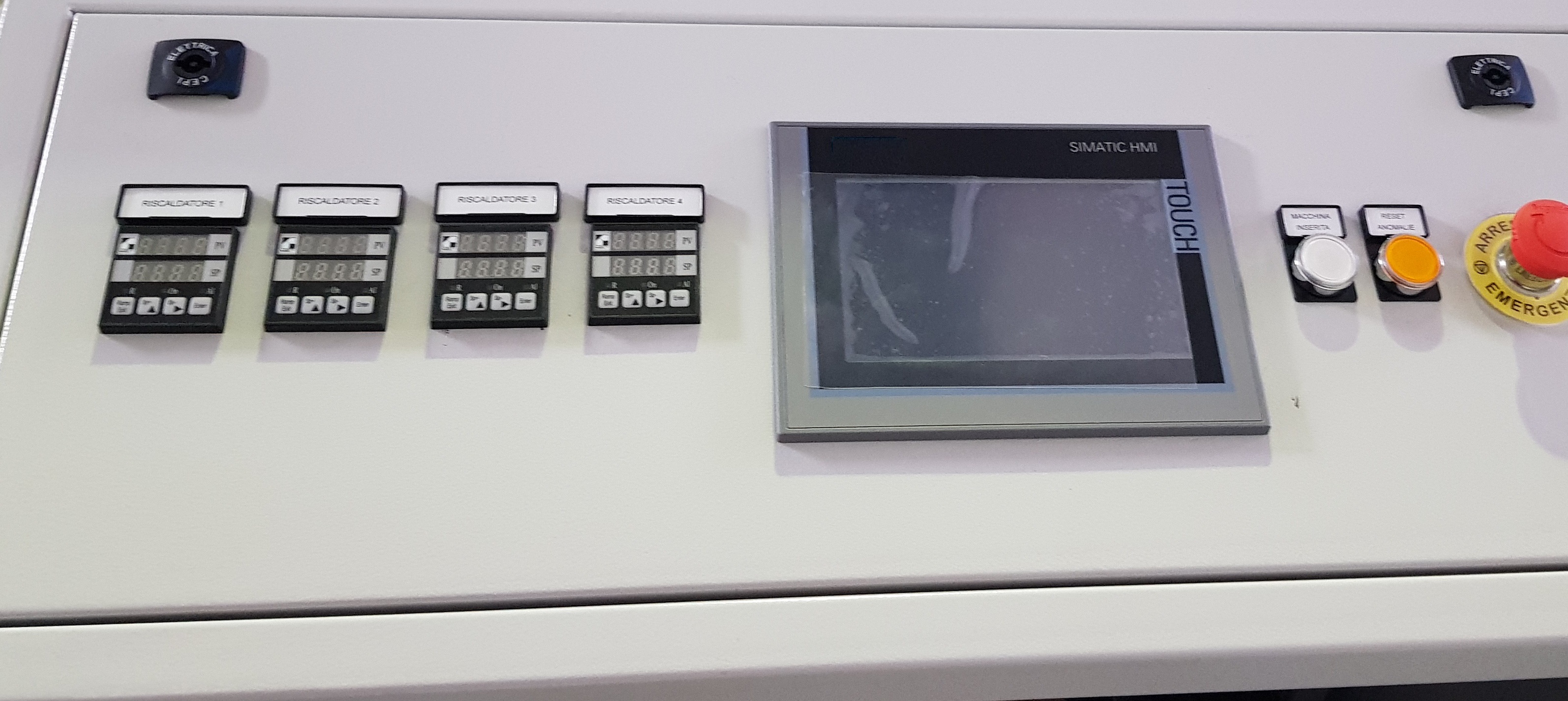

Updating

Study and implementation of electrical and mechanical modifications aimed at improving the quality and performance of an existing line with respect to current operation layout. Cost / benefit evaluation. This activity is preferably carried out at MEPALINE headquarters, where the equipment - once modified - can also be tested for the necessary checks before delivery to the customer.

-

Plant relocation

Disassembly, reassembly and commissioning of single equipment or complete lines on the occasion of transfer within the same plant or to a different production site. Analysis and consultancy to optimize layout configuration according to up to date production flow requirements, including necessary modifications and implementations.